Preparing Your Farm Equipment for Winter Storage

Proper winter storage preparation can extend your equipment life by years and prevent costly spring repairs. Our comprehensive guide covers everything from engine protection to battery maintenance.

Key Topics Covered:

- Engine winterization procedures

- Hydraulic system protection

- Battery storage and maintenance

- Fuel system preparation

1. Engine Preparation

Start by running the engine to operating temperature and changing the oil and filter. Fresh oil prevents acid buildup during storage. For diesel engines, add fuel conditioner and fill the tank to prevent condensation. Consider using a block heater if stored in unheated areas.

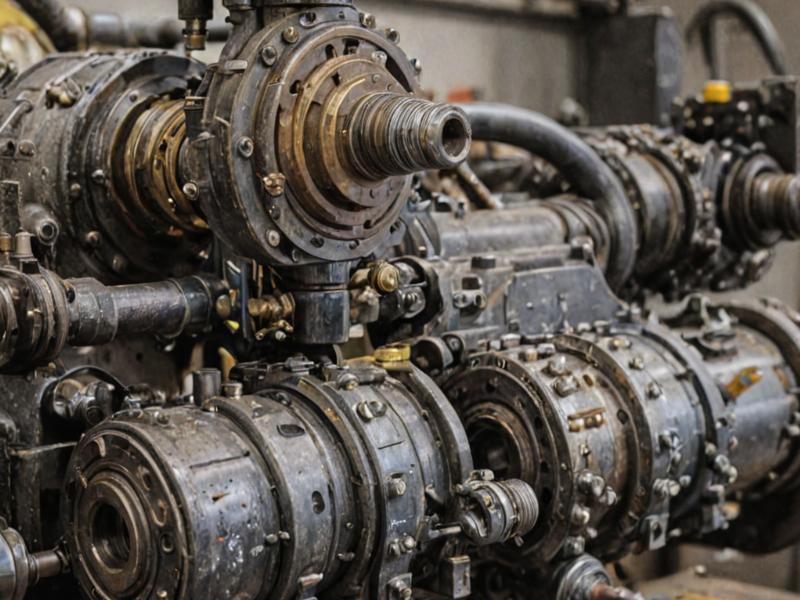

2. Hydraulic System Care

Operate all hydraulic functions to distribute clean fluid throughout the system. Check fluid levels and top off if needed. Consider changing hydraulic filters if they're near service intervals. This prevents contaminant buildup during storage periods.

3. Battery Maintenance

Clean battery terminals and apply protective coating. For long-term storage, disconnect the negative cable and store batteries in a warm, dry location. Use a battery tender to maintain charge levels. Frozen batteries can crack and require complete replacement.

4. Cleaning and Protection

Thoroughly clean all surfaces to remove crop residue and dirt that can hold moisture. Apply protective coatings to exposed metal surfaces. Grease all fittings and moving parts according to the maintenance schedule. Store in a dry, covered area when possible.

5. Tire and Implement Care

Increase tire pressure to maximum recommended levels to prevent flat spots. Store implements with weight off tires when possible. Cover or protect rubber components from UV exposure. Check and lubricate all implement bearings and moving parts.

Professional Storage Service

Blue Valley Farm offers comprehensive pre-winter equipment preparation services. Our technicians can handle all aspects of winter storage preparation, ensuring your equipment is ready for the next season.